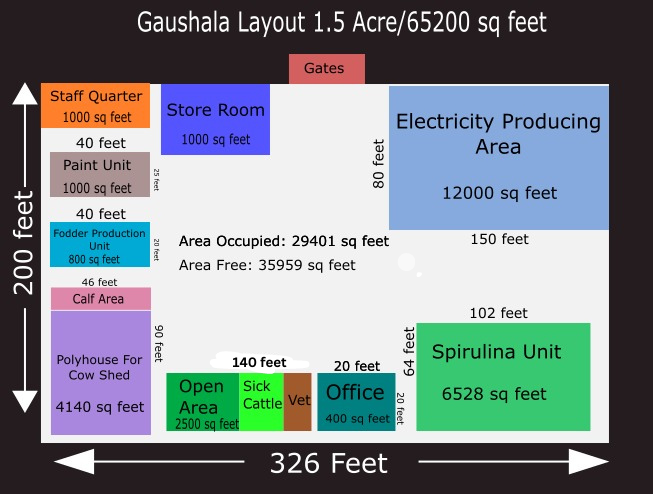

Layout of Gaushala

Our project encompasses all the major and minor aspects of a Self Sustainable Modern Gaushala, offering a comprehensive solution:

1. Integration of Modern Amenities: We have included all necessary modern amenities in our project, ensuring the Gaushala is equipped with the latest facilities while maintaining a budget-friendly approach.

2. Cost-effective Modern Equipment: We have incorporated essential modern equipment that not only enhances operational efficiency but also helps lower the overall cost of managing the Gaushala.

3. Emphasis on Employment: To promote employment opportunities and community involvement, we consciously avoid excessive reliance on high-tech equipment. Our goal is to engage society and provide valuable job opportunities.

4. Close to Nature: We prioritize maintaining a strong connection with nature. By adopting sustainable practices and focusing on environmental well-being, we strive to create a healthy and harmonious surrounding ecosystem.

Services

1. As an all-encompassing service provider, we take responsibility for our client's needs, from constructing infrastructure for a Self-Sustainable Modern Gaushala, procuring all dairy essentials, to marketing the produce.

2. We will develop a temperature-controlled, Self-Sustainable Modern Gaushala dedicated to cow rearing.

3. In our mandate, we will construct a polyhouse for the production of fodder and spirulina.

4. We will lease land specifically for cultivating Moringa leaves, a nutritious feed for our cattle.

5. We will procure the necessary medicine and food for the cattle, arranging storage for dry fodder within the Gaushala and supplying green fodder, such as wheatgrass and maize grass.

6. To ensure the Gaushala's smooth operations, we will supply and manage highly trained labor for all caregiving tasks.

7. Our responsibilities also include sourcing high-quality cattle for the Self-Sustainable Modern Gaushala, organizing medical facilities, and managing the production and distribution of milk, paint, manure, and electricity.

8. We will oversee the Gaushala's financial affairs, managing expenses and income, and ensuring our clients receive their returns.

9. Furthermore, we will take charge of produce storage, distribution, sales, and marketing, providing a comprehensive service for our Gaushala clients.

Temperature-Controlled Polyhouse

We specialize in constructing environment-controlled polyhouses, specifically known as fanpad system polyhouses. These polyhouses are fully automated and ensure optimal temperature control. By utilizing cooling pads and exhaust fans, the temperature inside the polyhouse can be maintained within a pre-set range, such as 25 to 30 degrees Celsius. To regulate moisture and humidity levels, our polyhouses are equipped with foggers that increase the moisture content, as well as overhead sprinklers to effectively cool the polyhouse during hot summer months.

Components Of Polyhouse

1. Air Circulation Fan (ACF):

Multiple rows of air circulation fans are strategically installed within the polyhouse to ensure the uniform circulation of air, thereby maintaining consistent temperatures throughout the space.

2. Matting for Polyhouse:

Waterproof matting is utilized to create a barrier between the ground and the polyhouse, preventing direct contact and keeping the interior clean. Additionally, it serves as a preventive measure, keeping soil insects from entering the polyhouse.

3. Electric Panel:

The electric panel is designed to control all the equipment based on the temperature and humidity settings established by the user. It acts as a central control system for efficient management.

4. Exhaust Fan:

Exhaust fans are employed to draw moisture through the pad and expel hot air from inside the polyhouse to the outside, contributing to effective ventilation and temperature regulation.

5. Temperature, pH, and Humidity Display:

A comprehensive display system is installed to provide real-time monitoring of temperature, pH levels, and humidity within the polyhouse. It includes a pH indicator and conductivity controller for precise monitoring of water quality.

6. Sensors:

Sensors are strategically placed to detect humidity and temperature levels and establish a connection with a mobile device through the Farmfluence system. These sensors allow remote monitoring and control of polyhouse conditions from any location. Additionally, they serve as early warning indicators, notifying users of any significant changes in the polyhouse environment.

7. Sprinklers and Fogger:

Foggers are strategically placed within the polyhouse to maintain a cool environment. Sprinklers are positioned above the polyhouse to provide external cooling during high-temperature periods, particularly in summer.

Clean Drinking Water For Cows

This unit offers several benefits for providing clean water to cattle:

1. Nature-friendly: The unit is designed with environmentally-friendly practices in mind, ensuring minimal impact on nature and promoting sustainable water usage.

2. Minimal water wastage: The unit is designed to minimize water wastage, allowing for efficient and responsible water consumption. This helps conserve this precious resource.

3. On-demand water availability: The system ensures that cattle can access water as and when they need it, promoting their well-being and hydration.

4. Labor-saving installation: With this unit in place, the need for manual labor in providing water to cattle is significantly reduced. The system operates automatically, saving time and effort.

5. Increased milk production: By ensuring a consistent and adequate water supply for cattle, the unit contributes to improved overall health and well-being. This, in turn, can lead to increased milk production from the cattle.

1.AUTOMATIC WATER BOWL FOR COW

The Cow Water Bowl is a semi-automated system that starts automatically when cows drink from it, reducing water wastage and ensuring a continuous 24/7 water supply. It is easy to handle, requires less cleaning compared to water tanks, saves manpower, and promotes cattle health with clean water supply.

2.INSTALLATION PROCEDURES

We will provide every cow there individual cow water bowl . It is installed in the walls of feeding tub and connected with pipes coming from water tanks

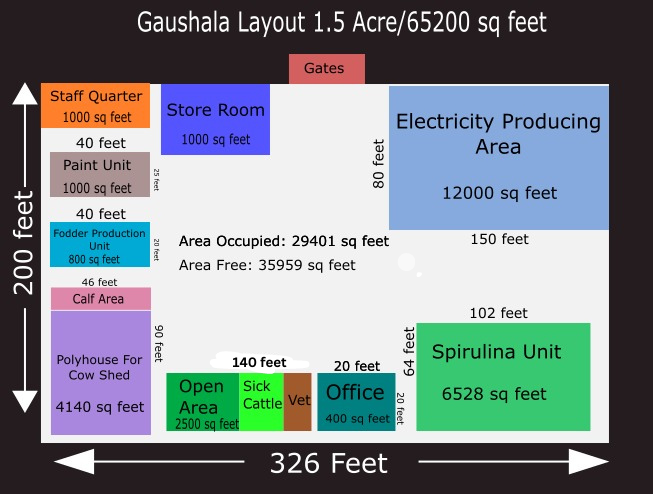

Fodder Production Unit For Cows

1. Fodder is ready in 7 days.

2. 1 Kg seeds produce 10 kg of green fodder.

3. One cattle needs 20-25 kg of fodder.

4. Roots and Seeds are consumed along with the green fodder (it gets wastes usually).

5. Sprouted seeds are better for cattle health.

6. Minimum water consumption.

Components of Fodder Producing Unit in Polyhouse

1. PVC Stand PVC Pipe size 1

2. PVC Four Way 1"

3. PVC Tee 1"

4. PVC Elbow 1"

5. PVC Band Plug

6. Fogger (80 foggers)

7. Filter

8. Plastic trays

9. Motor 0.50 HP

10. Timer

11. Plumbing material

12. Water tank 1000 litre

13. Shade net (90%)

Specification of Fodder

| Parameters | Conventional land-based fodder cultivations | Hydroponics system |

|---|---|---|

| Fodder production in days | 65-70 days | 7 days |

| Area required per day | One ha land to produce 600 kg | 50 sq mt to produce 600 kg per day |

| Water requirement | Very high at 30 litres per kg of green fodder | Minimal at just 1.5 to 3 litres per kg of green fodder |

| Soil fertility | Essential | Not essential |

| Fertilizer application | Required | Not Required |

| Fodder yield | Dependent on environment, cultivation practices, etc | No required climatic conditions |

| Labour requirement | Intense labour Required | Not Required |

| Fencing and farm | Required | Not required - can be undertaken in small shed or even under shade net |

| Green fodder utilization | Significant wastage | Almost no wastage |

Spirulina Producing Unit

1. Balanced diet for cattle in 10-30 grams dried.

2. 46 nutrients in proper ratio ore available in Spirulina.

3. Easy to produce and harvest .

4. Less than 1 manpower require.

5. All weather production.

6. Easy to store.

7. Best suited for Human and Cattle.

Components Of Spirulina Producing Unit

A motor-operated shaft with an attached paddle ensures continuous water movement, providing ample oxygen supply and maintaining a consistent water temperature.

To create cost-effective spirulina ponds, we utilize oval-shaped structures with a depth of 2.5 feet. These ponds are lined with a 500-micron plastic coating to minimize construction expenses. The water depth within the pond is maintained at 1 foot.

Nylon 500 GSM fiber cloth is utilized for efficient spirulina harvesting.

How to make Spirulina Production Unit

Spirulina algae can be economically grown on a large scale in oval-shaped ponds with a length-to-breadth ratio of 1:3. Intensive cultivation requires a 2.5-foot-deep pond with pH 9. Paddles and motors maintain continuous water movement for aeration. Harvesting of Spirulina begins 15 days after introducing cyanobacteria as an inoculate, yielding 8 grams per square meter daily.

Vitamin Content

| Vitamin | Quantity (per 100g) | %DV (per 100g) |

|---|---|---|

| Vitamin A | 9000 IU | 180% |

| Vitamin C | 10 mg | 18% |

| Vitamin E | 5 mg | 25% |

| Vitamin K | 25 mcg | 31% |

| Thiamin (B1) | 0.2 mg | 11% |

| Riboflavin (B2) | 0.3 mg | 16% |

| Niacin (B3) | 2 mg | 10% |

| Vitamin B6 | 0.04 mg | 2% |

| Folate (B9) | 94 mcg | 24% |

| Vitamin B12 | 0.03 mcg | 0.5% |

Mineral Content

| Mineral | Quantity (per 100g) | %DV (per 100g) |

|---|---|---|

| Calcium | 120 mg | 12% |

| Iron | 28.5 mg | 158% |

| Magnesium | 195 mg | 49% |

| Phosphorus | 118 mg | 12% |

| Potassium | 1363 mg | 29% |

| Sodium | 1048 mg | 43% |

| Zinc | 2 mg | 13% |

| Copper | 0.6 mg | 33% |

| Manganese | 1.9 mg | 94% |

Protein Content

| Protein | Quantity (per 100g) | %DV (per 100g) |

|---|---|---|

| Total Protein | 57.47 g | 115% |

| Essential Amino Acids* | N/A | N/A |

| Non-Essential Amino Acids* | N/A | N/A |

Nature Friendly/Chemical Free/Smell Free/Anti Fungal paint.

Reduces room temp by 6-7 degres.

Saves electricity.

Cost efficient distemper (Rs 120/- KG).

Average cattle waste is about 10 Kg. Giving Rs 50 per cow dung, making animal self-dependent.

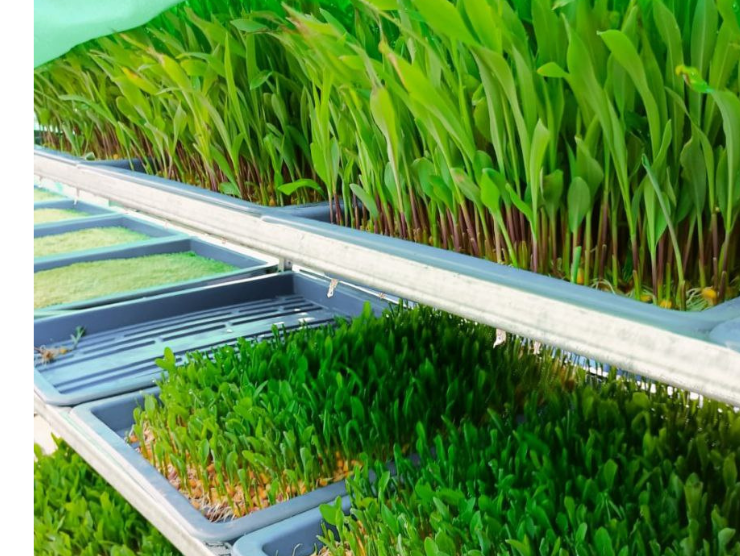

Paint Production Unit Components:

1.Water primer machine 2000

2.Sand mill 200 litre

3.Pugh mill 1 tonn

4.100 litre boiler

5.Stock pump

6.TDR 10

7.Bleach tank 600l litre

8.Primer tank 2000 litre

9.Weight machine

Quality of paint produced

| Property | Khadi natural paint | Other paints in market |

|---|---|---|

| Antibacterial | Antibacterial | Not Antibacterial |

| Antifungal | Antifungal | Not Antifungal |

| Environmental supplement | The main ingredient is cow dung which is available naturally | Harmful chemicals used |

| Heat resistance | Ability to behold external temperature . | Can’t stop heat |

| Odourless | 120-225 rupees Per litre of kg. | 250- 500 Rs per Litre |

| Economical | No smell of any kind | Foul smell |

| Non toxic | No toxic elements.c | Use of harmful toxic chemicals like Xylene, Ethyl Acetate, Glycol, Methylene Chloride et |

| Free from heavy metals | No heavy metals used. | Used in the manufacture of heavy metals etc. |

Amount of Paints Produced and Government Support :

The basic unit of 15 lakhs will produce 500 litres of paint per day. 1 litre of Paint C.P 65 Rs -120 Rs and S.P 120-250 per litre. This project is supported by KVIC and NITIN GATKARI our Kadhi and gram udoy minister.

Marketing of paints produced:

Can be sold in KVIC OUTLETS present in entire

country.

KVIC takes 10-30 % of profit.

Can be sold in Amazon and Flipkart type sites

Can be sold by individual salesman.

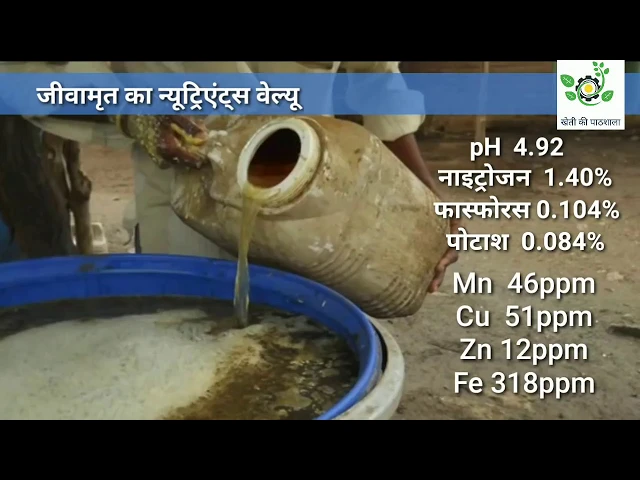

Jeevaamrit

Jeevaamrit is an organic fertilizer that is commonly used in natural farming practices, particularly in India. It was popularized by Subhash Palekar, a proponent of the Zero Budget Natural Farming (ZBNF) method. The main benefits of using Jeevamrit are:

1. Nutrient-Rich: Jeevamrit is rich in micro and macro nutrients essential for plant growth. The nutrients are directly available to the plants, helping them grow healthily.

2. Microorganisms: It contains beneficial microorganisms that help improve the quality of the soil. These microorganisms break down complex organic matter into simpler forms that plants can absorb. They also help in maintaining the soil's health by decomposing dead plant material and other organic matter.

3. Environmentally Friendly: Jeevamrit is completely organic, so it doesn't contribute to pollution or harm the environment. It doesn't contain any harmful chemicals, unlike many commercial fertilizers.

4. Cost-Effective: It can be made at home using locally available resources like cow dung, cow urine, jaggery, flour and soil. This makes it a cost-effective solution for farmers.

5. Sustainable Agriculture: Using Jeevamrit supports sustainable farming practices, as it helps maintain the fertility of the soil in the long term, unlike chemical fertilizers that can degrade soil quality over time.

6. Improves Crop Yield: Many farmers have reported improved crop yield after using Jeevamrit, as it provides the necessary nutrients and improves soil health.

7.Resilience to Pests and Diseases: Healthy plants grown with Jeevamrit are often more resilient to pests and diseases, reducing the need for chemical pesticides and fungicides.

8. Improves Taste and Quality of Produce: Some farmers have reported that produce grown using Jeevamrit has a better taste and quality compared to those grown with chemical fertilizers.

Moringa production unit for cow

1. Super food on earth.

2. 5-10 gram per cattle can keep them healthy

3. Available in weather.

4. Oxygen producer tree good for environment.

5. Leaves provide balance diet to all animals.

Moringa production

Moringa thrives in soil with excellent water percolation capacity. With soft leaves and stems, it becomes a favored food choice for cattle. This remarkable plant is a nutritional powerhouse, abundant in vitamins and minerals. Proper cultivation can yield a remarkable 100 tons per hectare. Once planted, it can be used for multiple years, ensuring long-term benefits. The National Dairy Development Board endorses Moringa as the best fodder, supported by a collaborative report with the Institute de Ciencia Animal, Cuba. Comparing it to mulberry and tithonia, Moringa emerges as the superior choice. Its chemical composition makes it an excellent feed option for cattle and small ruminants, offering high nutritional value even for non-ruminants. Embracing Moringa helps enhance the overall nutritional value of the feed, benefiting both the animals and the farmers.

Advantages of Moringa Over Traditional fodder

| Traditional Farming | Moringa farming |

|---|---|

| Average Protein 8-10 % | Average Protein 16% |

| 1 hectare -50 -60 ton | 1 hectare -100 ton |

| Not available throughout years | Available all the time in year |

| It costs Rs 2 for 1 kg | It costs Rs 1. 50 for 1kg |

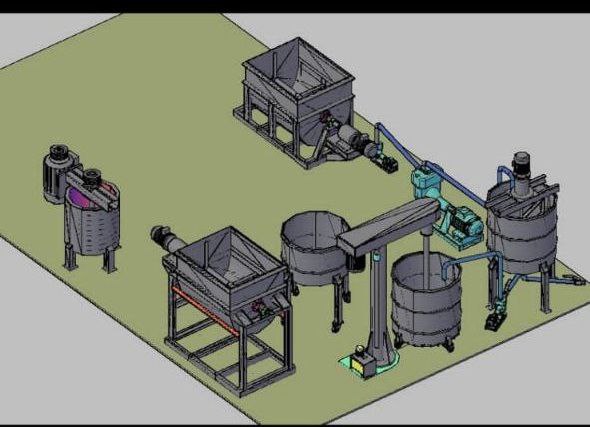

Electricity Producing Unit

1. With just 8 hours of Bull walk, a single bull can generate a minimum of 40 units of electricity daily, a remarkable feat.

2. Installing this innovative system requires only a compact 200 sq feet area, making it space-efficient and adaptable to various setups.

3. By producing electricity, a bull becomes a valuable asset, capable of earning Rs 200 per day, contributing to its own upkeep and beyond.

4. This groundbreaking technology transforms Gaushalas into self-sufficient entities, aligning with the ethos of a Self-Sustainable Modern Gaushala. Meeting the electrical needs of the facility becomes effortlessly achievable.

5. With the flexibility of usage at any time of day, this electricity-producing unit provides uninterrupted power supply, catering to the diverse requirements of the Gaushala community.

Electricity Producing Process

In the Self Sustainable Modern Gaushala, just as cows require daily exercise, oxen and bulls are meant for hard work, capable of 6 to 8 hours of labor. With the guidance of esteemed scientist Dr. Shiv Darshan Malik, honored by the Prime Minister of India, we've tapped into the incredible energy potential of compressed air. Our ingenious mechanism operates on compressed air, utilizing the strength of bulls to compress the air. With every hour of rotation, the machine generates 5 hours of electricity, powering a 1 kW generator for 5 hours. Through the rotational movement of cows and bulls, we compress the air in a specially designed compressor. This compressed air is stored in a 10,000-liter air tank and then channeled through an air motor and alternator to generate electricity. To achieve optimal performance, we employ three such mechanisms, each equipped with a 10,000-liter tank, a generator, and an air-powered motor. It takes the force of three bulls or cows to compress the air to a pressure of 91 PSI. To generate 1 kilowatt of electricity, we require a continuous airflow of 12 to 14 liters per second. By implementing this innovative unit, we revolutionize electricity production in the Gaushala, harnessing the inherent power of cattle and creating a sustainable energy source for a brighter future.

Management of Milk

Milking Machine

Distirbution Jar

Deep Freezer For Chilling Milk

Return On Investment

A. The company promises to provide a monthly return of 2.5 lakh Rupees on an initial investment of 70 lakh Rupees, under the terms specified below. The Gaushala will be under the company's control upon construction, with client's consent, and pursuant to a legally binding agreement.

B. Initially, the Gaushala will be registered in the client's name for the purpose of securing loans and subsidies.

C. The client's return is assured via the provision of post-dated cheques.

D. All assets of the Gaushala, including cattle and infrastructure, will be insured. The company will bear the cost of the insurance premiums and handle any claims, should they arise.

E. The company reserves the right to replace any cattle or machinery, as deemed necessary for the improvement and betterment of the Gaushala.

F. Any reinvestment required for the operation of the Gaushala will be undertaken by the company.

G. An agreement will be made with the client for a term of five years. If the client wishes to extend the term, the agreement can be revised for another five years under mutually agreed-upon terms.

H. Upon the completion of the term, the ownership of the Gaushala will be transferred to the client.

I. The client will receive payment between the 1st and the 10th of every month.

J. If the company delays payment, it will be obligated to pay an annual interest of 24% on the delayed amount.

K. As the construction of the Gaushala project will take two months, the first payment will be due in the third month.

L. Any legal disputes arising from this agreement will fall under the jurisdiction of Lucknow.

Email Id : bijendragaushalapvtltd@gmail.com

Phone no. : 9616910859

6393503007

Address: A-2, Akash Villa, Sector C LDA Colony, Kanpur Road Lucknow 226012

LinkedIn :bijendra-gaushala

Instagram :bijendra-gaushala

Facebook :bijendra-gaushala

Twitter :bijendra-gaushala

Youtube :bijendra-gaushala